About Bently and New Way

In 2014, New Way Air Bearings®, based in Aston, Pennsylvania, bought many of the remaining assets of Bently Pressurized Bearing Company. One of New Way’s strengths is to introduce gas bearing technologies into new industries. New Way® has over 25 years of experience manufacturing air bearings, which are used by the machine tool, semiconductor, medical and other industries. It is New Way’s mission to expand upon the work of Don Bently, former owner of Bently Nevada and Bently Pressurized Bearing Company, and to further develop the Bently Bearings™ brand.

Don Bently died on Oct. 1, 2012, and is best known for developing eddy current probes and for his studies in the area of rotordynamics. After spending a lifetime of studying rotor instabilities, he was keen to develop techniques to actively control instabilities. Bently demonstrated that by changing input pressure, and hence the stiffness of his bearings, the natural frequency of the rotor system could be tuned away from instabilities, from outside the machine.

Drew Devitt, founder and chairman of New Way Air Bearings®, notes, “As I studied rotordynamics and bearing technology in the turbo industry, I was continually led to the works of Don Bently. Don saw the potential for externally pressurized gas bearings to replace hydrodynamic oil bearings, and even eliminate whip and whirl, simplifying rotor dynamic issues. I believe that with New Way’s porous media technology I can make Don’s dream a reality, and overcome the limitations of the orifice technology he was using.”

Drew Devitt notes that from Don Bently’s book The Fundamentals of Rotating Machinery Diagnostics (especially chapter 23), “the reasoning and equations are the technical foundation for dynamic models and ultimately the commercial success of the externally pressurized bearing technology we believe in”.

History of Bently Bearings

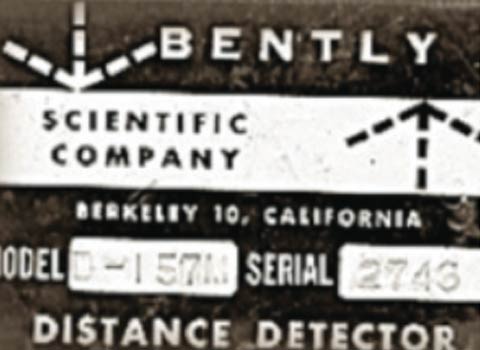

The roots of the Bently Pressurized Bearing Company go back to 1955 and the Bently Scientific Company in Berkeley, California. Don Bently formed his own company to design, build, and sell his eddy current “distance detectors” via mail order. His conversion of the basic transducer system design from vacuum tubes to transistors made it robust and cost-effective for industrial applications. In 1961, Bently Scientific moved to its present-day location in Minden, Nevada, a Corporation to reflect its new home.

The proximity probe soon found its niche as a sensor for directly observing the position and vibration of rotating shafts inside industrial machinery, and Bently Nevada’s business grew exponentially during this period. In the mid-1960s, Bently Nevada began offering monitoring systems as well as transducers. The monitors accepted inputs from Bently transducers, provided continuous monitoring of vibration and position, and compared monitored parameters against user-established alarm limits. In the years since, the number of monitored parameters has grown to encompass rotative speed, phase, temperature, thermal expansion, valve position, pressure, and numerous other machine-related conditions.

In the 1970s, Bently Nevada developed a services organization to diagnose machinery problems as well as install, calibrate, and repair instrumentation. Bently also began offering training to customers on the fundamentals of vibration, the use and calibration of instruments, and machinery diagnostics. The 1980s saw the establishment of Bently Rotor Dynamics Research Corporation, founded to conduct fundamental research, led by Dr. Agnes Muszynska for many years. Bently Nevada also introduced computerized, online, condition monitoring software as part of a growing emphasis on machinery protection and proactive management of machinery through the use of real-time data. The 1990s brought further refinements in Bently Nevada’s capabilities and scope, adding thermodynamic condition monitoring capabilities.

At the same time, a significant growth in its services organization took place to address the shrinking staff of machinery engineers in many customers’ plants and to provide system integration and turnkey project management expertise. In keeping with the mission of the Bently Rotor Dynamics Research Corporation, research began on the development of a new type of fluid bearing designed to overcome fluid induced instabilities that were commonly observed in traditional bearing designs. This early research would lay the foundation for what was to become the Bently Pressurized Bearing Company.

In 2002, Bently Nevada Corporation assets were purchased for $630 million in a friendly acquisition by General Electric Power Systems division. The purchase of Bently Nevada enabled Don Bently to focus on development. Following the sale, Bently renamed his company Bently Pressurized Bearing Company to better reflect the focus of the new activities. Don used orifice compensation and metal to metal bearing faces in his gas bearings designs. He met with limited success. October 1, 2012 Don Bently died, New Way had just exhibited at the TPS 2012 in Houston, our first turbo related show. Don was an expert at rotordynamics but a novice with gas bearings. New Way knows gas bearings and intends to pick up where Don left off, by taking a page out of his rotor dynamics teachings.

Aerostatic Bearings

Hydrostatic Bearings